10L Ink Bead Mill Machine 5-15um Paint Ink Milling Machine

Applied In Paint Coating Ink Food Process Large Flow And Energy Saving 10L 20L 30L Bead Mill Machine

The main feactures of Bead Mill Machine:

1. Different materials for meeting dirffent needs :Adopted high abrasive-resisting materials:silicon carbide ceramics,like hard alloy, 9Cr18Mo alloy steel, SUS 304 stainless steel, to guarantee strengthen working life of bead mill machine. Meanwhile we suggest the suitable grinding beads to match with the inner chamber materials.

2. Decrease the temperature:

Applied self-owned double spiral cooling technology to enhance the space of heat rejection, with superior material with good thermal conductivity and lower the temperature before coollant come in pipe. also temperature is lower if choose the inner chamber of Silicon carbide ceramics.

3. Strenghten the fineness:

The different fineness after grindinig can be reached for your different demands, the smallest grinding media of 0.1mm with 200-300nm.

4. Enhance the efficiency:

High efficiency with enegry saving, have indepently grinding and dispersing technology, nomarlly the efficiency is higher 10-30% than traditional machines. also it's more better if choose the temperature is better.

5. Reduce the workforce with indicator light

One worker could easily operate and manage 5-10 sets mill machines if mills add the indicator light, decrease the cost of humen. the mill machines will add more if need central control system. It's will be automation and intelligence and saving more labor cost.

The working principle:

The working principle is to use the material pump to feed the solid-liquid mixture material that has been pre-dispersed and wetted by the mixer into the chamber, and the material and the grinding medium in the chamber are stirred by the high-speed rotating disperser, so that the solid particles in the material and The grinding media produce stronger collision, friction, and shearing effects with each other to achieve the purpose of accelerating the grinding of fine particles and dispersing aggregates. After grinding and dispersing, the material passes through a dynamic separator to separate the grinding medium and flows out of the discharge pipe.

Main Technical Parameter of 30L Wet Milling Equipment

| NO. |

Main parameter |

SP30 |

Note |

| 1 |

Main motor power(kW) |

30 |

3phase,230V 50Hz |

| 2 |

Effective Volume(L)

|

30 |

|

| 3 |

Water presure Mpa |

0.3 |

|

| 4 |

Cooling water consumption

(L/min)

|

2.5 -3m3/h

|

The lower limit can be

selected for the water consumption, in case that the cooling water temperature is lower than 10℃.

|

| 5 |

Overall dimension (mm) |

1740*820*1600 |

|

| 6 |

Weight (kg) |

1300 |

|

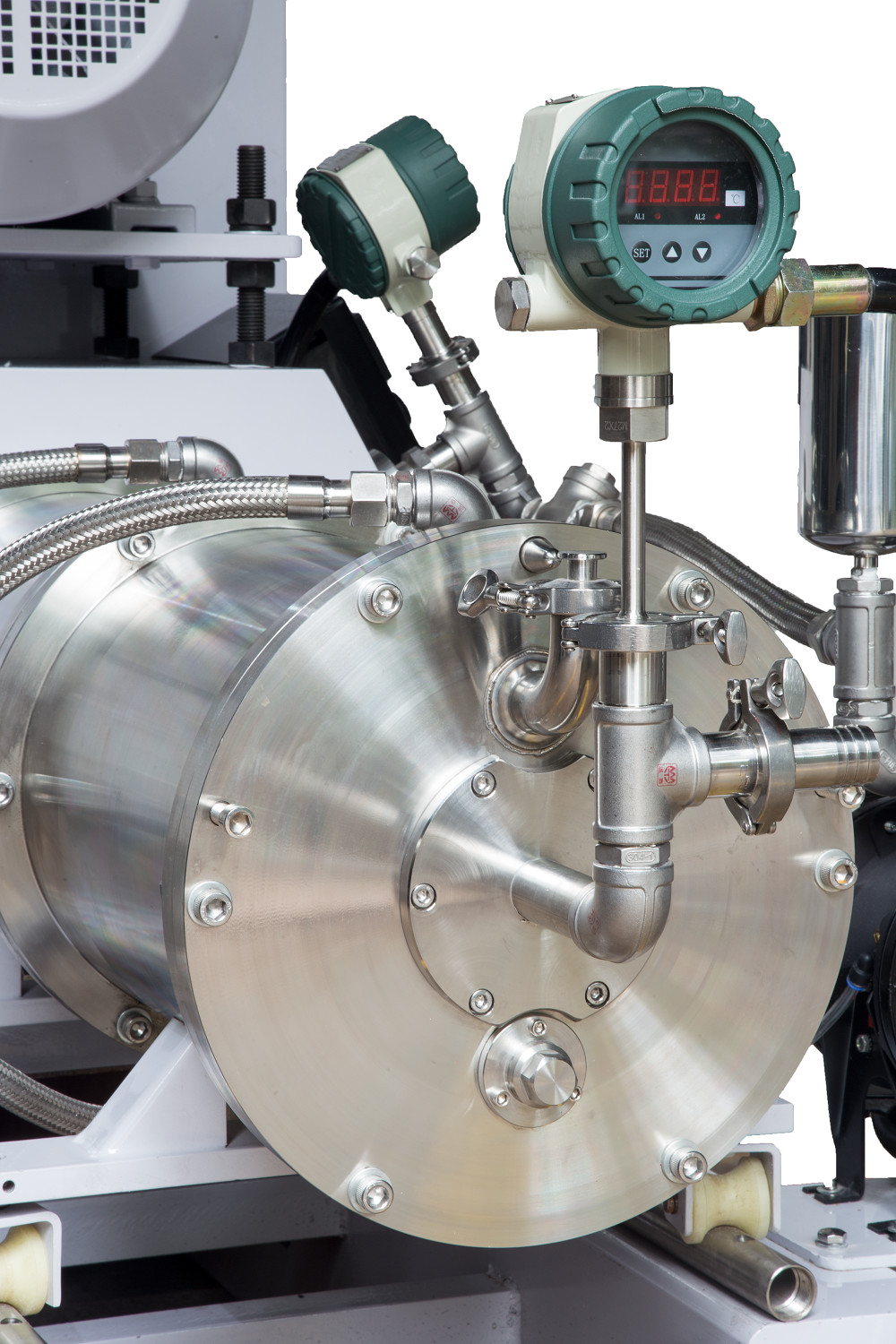

Configuration instructions information of Wet Milling Equipment:

1. Outer Chamber: 304 stainless steel

2. Inner Chamber: silicon carbide ceramics

3. Dispersing shaft: 40Cr with hard chromium plating

4. Dispersing disk: 304 Stainless steel

5. Mechanical seal: Double Mechanical seal with Pressure of 0.45 Mpa

6. Feeding and discharging end covers on the chamber: 304 stainless steel

7. Turbine centrifugal separator and pigs: 304 stainless steel and YG6 pines.

8. Static discharge screen ring: 304 stainless steel screen ring with 304.Gaps: 0.5mm.

9. Feeding pump: 1" ARO pneumatic diaphragm pump.

10. Electric Appliance configuration: Non Explosion-proof machine, suitable for water base materials, explosion-proof motor 30kW. Non Explosion-proof parts: operation column,electrical appliance boxes;electric contact pressure gauge, temperature,solenoid valves with Non EX-proof electrical contacts.

11. Fasteners and connecting parts: Stainless steel clamp-type connecting parts.

The Allwin history

Since founded in 1993, Allwin have been concentrating on grinding-dispersing technologies for half a Century. Mr. Wang Yongqi, Our Chief Engineer of Allwin Machine Equipment Co, Ltd and senior engineer developed the Chinese first sand mill in 1967.Over the past 24 years; Allwin machine has made great achievements through bold innovation and continuous practices. We have 11 patents about bead mills and won the certificate of IPR compliance. We could offer both grinding bead mills and production lines for wet grinding users. In the past 6 years, we made more than 300 experiments for dispersing and grinding, have more than 1300 bead mills applications in different fields.

The customer site picture

The packing and delivery : firstly anti-abrasion film and packed in wooden boxes, then seashipping by FCL or LCL container.

Note:

1.We will recommend the suitable bead mills according to your information and demand, such as industry, fineness, temperature, viscosity,production capacity etcs.

2.The Materials of inner chamber and Dispersing disks can be chosed according to your different grinding materials and industries.

3.The control system will matching of different demand, such as PLC or traditional Button type.

If need more detailed information, please don't hesitate contact us, Also Warmly welcome to visit us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!